Bottomless water block – The fact that in the same situation people have the same thoughts, I was convinced more than once. This is especially noticeable when you study the materials of some long branch in the conference of the site. Periodically, someone comes up with a thought that was discussed a couple of months ago. And if you dig around, you will find that the idea was expressed a year, or even a couple of years ago. It happens that the idea is very interesting, but it drowns in countless pages. Not always and not everyone succeeds in testing the idea experimentally.

This happened to me too. Some funny idea will come to mind and it seems that no one has come up with such a thing for sure. But, it turns out, there were already people. It’s a shame, of course, but I also consider it wrong to proclaim myself the author of such ideas. So it turns out that such ideas are, as it were, “popular”, and naturally belong to this very “people”. And since the idea is as it were general, then there is no one to check it. So this reasoning would have remained with me, if not for the case.

Somehow, while switching channels on my TV, I accidentally stumbled upon a program called “Myth Busters”. In this program, two Americans repeated in “laboratory” conditions the situations set forth in the bikes that everyone probably heard. And they either experimentally confirmed the possibility of what was told, or denied it as impossible. They investigate both “urban folklore” and historical legends. So they tested the legend about how the inhabitants of Syracuse besieged by the Romans with the help of polished copper shields (with the filing of Archimedes) set fire to the Roman fleet. They fired from a self-made wooden cannon. They checked the possibility of killing with an ice bullet … And much, much more.

I liked the very idea of the program very much. And it seemed interesting, following the example of these two geeks, to begin my test. Not legends. And the ideas are well-known, but never tested. Of course, if you dig around, it turns out that I have already done such a check a couple of times. This is a comparison of the efficiency of one and two auto-ovens in a water cooling system – “Two is not always twice as good.” And check whether the performance of the radiator from the auto-oven will increase if the distance between the radiator fins is increased – “Modernization of the radiator of the water cooling system (auto-oven)”. Yes, and something else … But there are still many, many such “legendary” inventions and inventions. For example, it has not yet been verified whether the efficiency of a cooler on heat pipes will increase if these pipes are cooled not with air, but with water? And similar delights. But today something else will be tested.

One such “eternal”, I am not afraid of this word, folk theme – “water block without a bottom”. The train of thought is this – why first cool the water block with water, which in turn will remove heat from the processor, when you can immediately cool the processor with the same water. The “extra” link is excluded. The idea is beautiful. There is no need to manufacture the most expensive and time consuming part of the water block. One thermal transition is eliminated. Not even one, but two. Processor-thermal paste, thermal paste-water block. But there are also disadvantages. The processor core area is small. Will it be enough for heat dissipation? What about an overclocked processor? Still, water cooling means overclocking.

But on the other hand, now all modern processors are equipped with protective covers, which also perform the functions of a heat spreader. Why not use this cover as the bottom of the water block? Besides, it often happens that these covers have a curvature, which affects the adherence of the cooler to them. Which, in turn, has a bad effect on overclocking. We immediately get away from this problem.

All these thoughts have been swirling in my head for a long time. But there was no easy solution to this beautiful idea. I didn’t want to glue some containers with fittings to the processor, and even more so to solder it with low-melting solder. I could not believe in the reliability of the adhesive connection, and I did not want to lose the guarantee. But then I came across an electrical junction box. Her openings for the entry of wires were closed with corrugated rubber caps. Taking a close look at the cap, I saw that if you cut off the top of the cap, it will come out with a beautiful elastic pad. And I can easily cut the cover with fittings from acrylic glass. The photo shows the box itself, a whole cap, cut, and of the processor itself.

For the manufacture of the cover, of course, it would be better to take thicker acrylic, but only 3 mm was at hand. Will go for a trial. I will not tell you how to cut plexiglass. I think everyone knows this. That’s what I did.

announcements and advertisements

3060 cheapest in Citylink

Many MSI RTX 3060 on sale

First-hand Z590 motherboards at very good prices

RTX 3070 cheapest at Compeo.ru

The best GTA 5 server – real cars, factions, gangs, no bots

3060 Gigabyte Vision in Citylink

RTX 3060 12Gb in XPERT.RU – be in time 🙂

-20% on an almost gaming computer – nowadays it also happens

Galaxy S20 family price crash 25% discount

30% discount on 75 “4K Samsung – cheap drain in Citylink

RTX 3070 at XPERT.RU at the lowest prices

75 “LG IPS for 4,736,000 rubles – see specifications

Lots of RTX 3090 in XPERT.RU

The bottom of the rubber washer has a tapered edge that should fit snugly against the processor cover.

And I will say a few words about the installation of the fittings. I had the fittings ready. But with carvings. Therefore, I drilled holes in the acrylic with a slightly smaller diameter than the threads on the fittings. And the fittings themselves were heated on a gas burner and hot-screwed into the lid. How to cut the thread. Then, of course, he twisted it and wrapped it with a car sealant named after me.

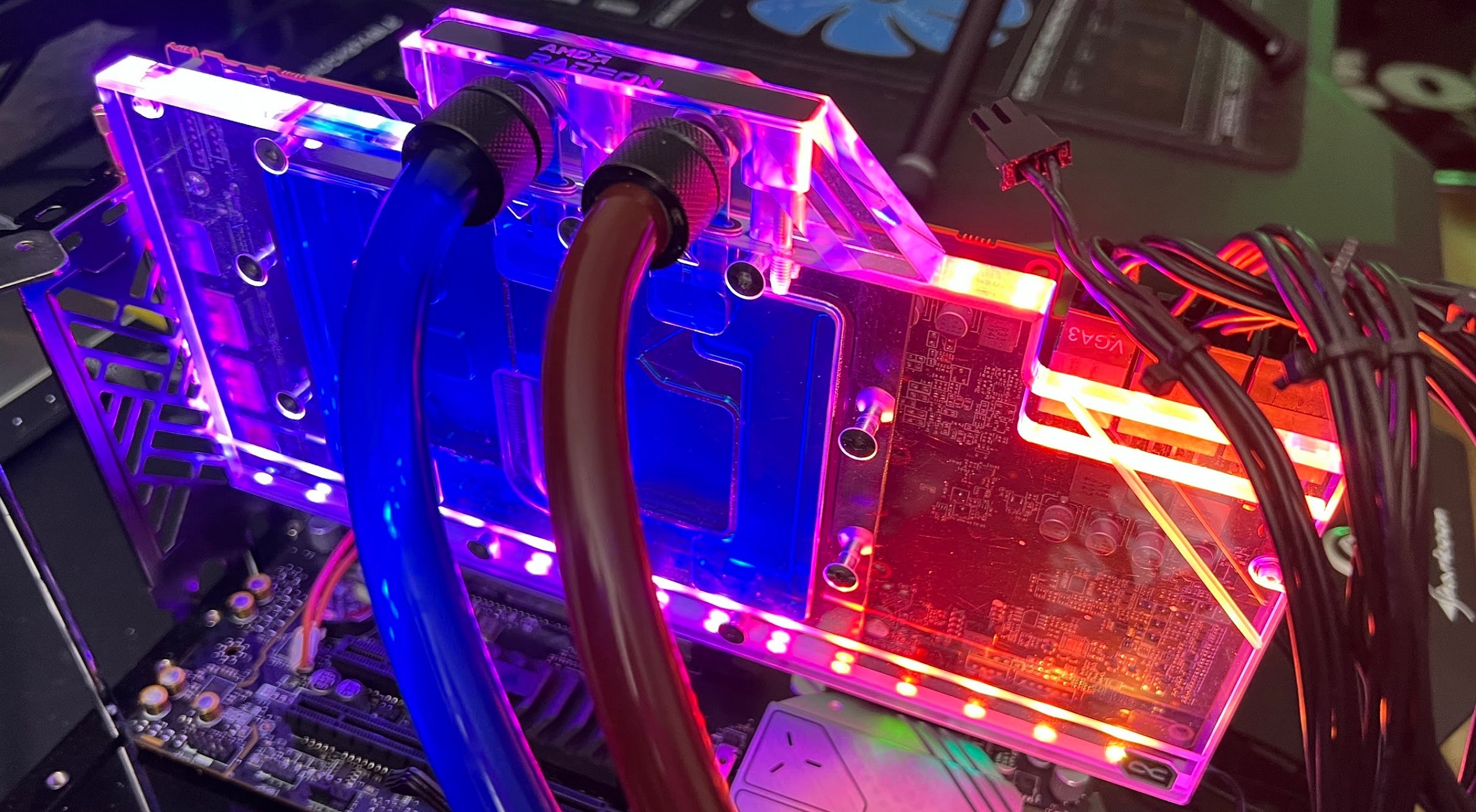

The result is a strong and at the same time tight connection. For ease of installation, I glued the rubber gasket to the acrylic cover with a sealant. I dried it for a day. The result is such a water block without a bottom.

For some reason I didn’t have enough courage to put it on real iron, so I checked the product for leaks in conditions close to “combat”.

Everything worked out, the water did not flow out. Let’s start testing. I will compare with a homemade copper waterblock, which has served me faithfully for a pretty decent period of time.

The processor waterblock is milled from a 17 mm thick copper plate. Dimensions 76 x 67 mm. Has a needle-like design. Three-shtutserny. The inner diameter of the fittings is 10 mm. Sole thickness 3 mm. Somewhat monstrous in appearance, there are not enough stars from the sky, but I am satisfied with the performance.

The water cooling system is described in detail in the article “The Three Years Path to Silence.” Briefly, I will remind you that a water cooling system is located in a homemade case. An aluminum heating battery is used as a radiator. Heat carrier – antifreeze, is pumped by a circulation pump. To connect the water blocks, collectors from the water “warm floor” are used, which makes it possible to quickly change the water blocks without draining the coolant. Until recently, the computer looked like this:

But a couple of months ago, some of the components from this product were removed and used in the next project.

Therefore, the current appearance of the system unit is somewhat different. And the video card is not used 7800.

The test bench configuration is as follows:

- Processor – AMD Athlon 64 3200+

- Motherboard – DFI Lan Party UT nF4 SLI-D

- Video card – PCI Matrox

- Memory – Corsair XMS Xpert PC3200 1 module 512MB

- Hard Drive – Seagate 160Gb

- Power supply unit – Powerman 420 W

- Thermopaste – KPT-8.

Let’s look at the traditional copper water block first. The processor “warmed up” S&M v1.7.3. (beta). With a system water temperature of 26 degrees, the maximum temperature of an overclocked processor was 35 degrees Celsius. Then I overclocked the processor to 2700 MHz with a voltage increase to 1.55. With a water temperature in the system of 26 degrees, monitoring at S&M recorded a maximum temperature of 43.3 degrees.

We proceed to install the “bottomless”. I put it on, open the taps, fill it up, turn on the pump and watch for a flood. I always use cambric cloth or a piece of newspaper for insurance. Immediately, in case of failure, wet spots are visible.

All right. A couple of years ago, after the first turn on, there was always a small waterfall. Marveling at the increased skill level, I turn on the computer. No explosions, no flashes, not even the most overwhelmed fireworks. Ordinary boring inclusion. Not even interesting.

I’m starting to compare. First, the processor is in normal mode. Sadly, the “bottomless” loses to the water block. And, by the standards of water cooling, decent. S&M monitoring fixes a maximum of 40.4 degrees. At a water temperature of the same 26. Loss of 5.4 degrees! But this is at the first speed of the circulation pump.

Let me remind you that I have a Grundfos UPS 25-40 circulation pump in my water cooling system. It has a three-speed switch. Working at first speed, it provides a capacity (actual measured by the water meter in the system) of 370 l / h. And on the third – 580. The copper water block was also tested at the first pump speed. I do not use the second and third pump speeds under normal conditions. At these speeds, with prolonged operation (more than an hour), the pump begins to warm up. And the pump is cooled by the liquid pumped by it. The result is that the temperature of the coolant rises, which negates all the benefits of the increased flow rate.

What happens if you repeat the test at third speed? Perhaps the performance of the “bottomless” will be equal to the waterblock? No sooner said than done. Only the result is not encouraging – 39.7. True, the water temperature rose by two degrees. That is, in the best case, an increase in efficiency by two degrees.

Now let’s see how the “bottomless” one will cope with the overclocked processor. Again I drive from BIOS – 2700 MHz with increasing the processor voltage to 1.55. The system failed the S&M test. I tried the third pump speed – the same result. The “bottomless” did not cope with overclocking.

The result – the waterblock without a bottom lost on all points (except for the cost) to the copper waterblock. Is the myth destroyed?