introduction

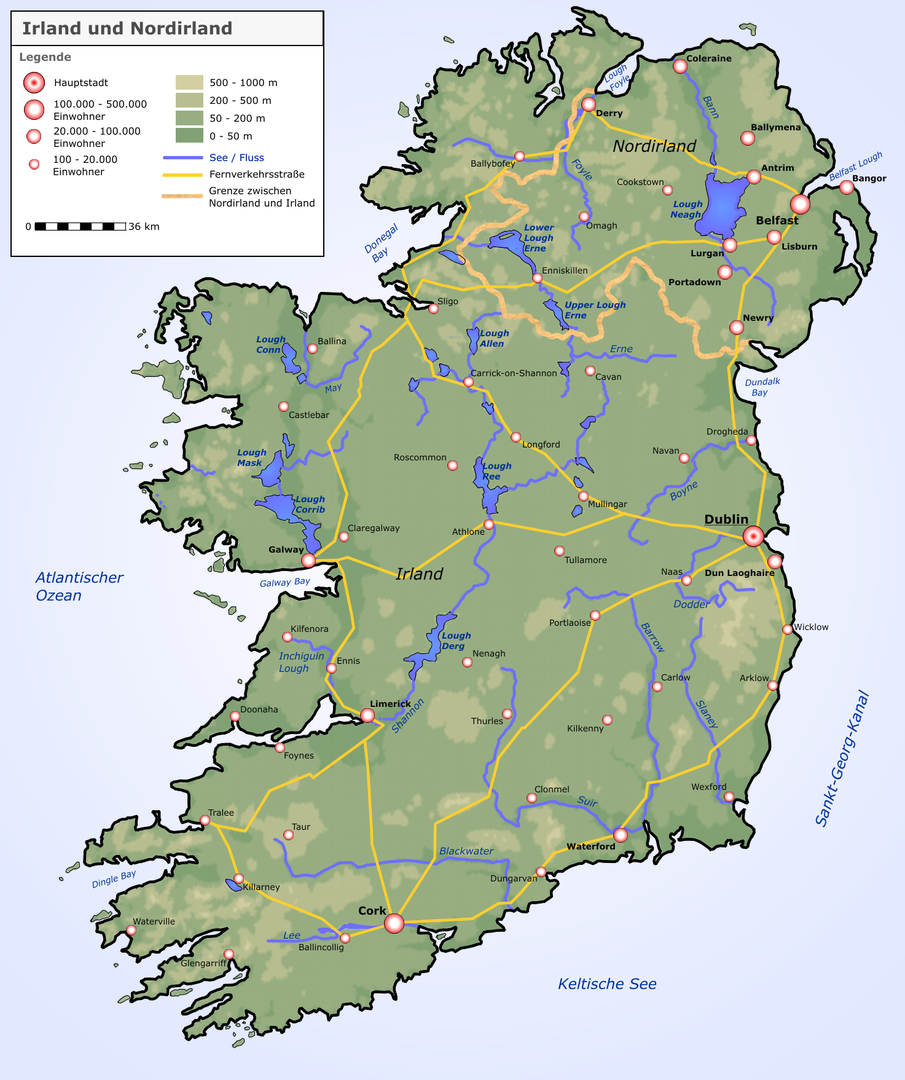

At Seagate's invitation, a few days ago, along with colleagues from England and France, we had the opportunity to visit the hard disk printhead plant in Derry, Northern Ireland, and to have a little chat with the engineers. The result was not only an insight into the production of print heads for hard drives – Seagate Springtown is the world's largest factory of this kind – but also a small look at which write technologies will be used for ever higher storage densities in the next few years.

Arrival and factory tour

The journey was a little adventure in itself. A flight to Belfast, as the colleagues from France and England could take, would have been ideal. Since Belfast is not served from Germany, Aer Lingus initially went from Frankfurt to Dublin. The friendly Seagate driver service driver was already waiting at the airport with a sign that greeted in broad Derry dialect, which even after a good three hours drive by two people did not quite understand. After a few hours of exploring the city – the flights to Derry arrived later – there was only a dinner for the first day with Ian O'Leary, Seagate's communications manager for Europe, and a quick trip to an Irish pub on the Program.

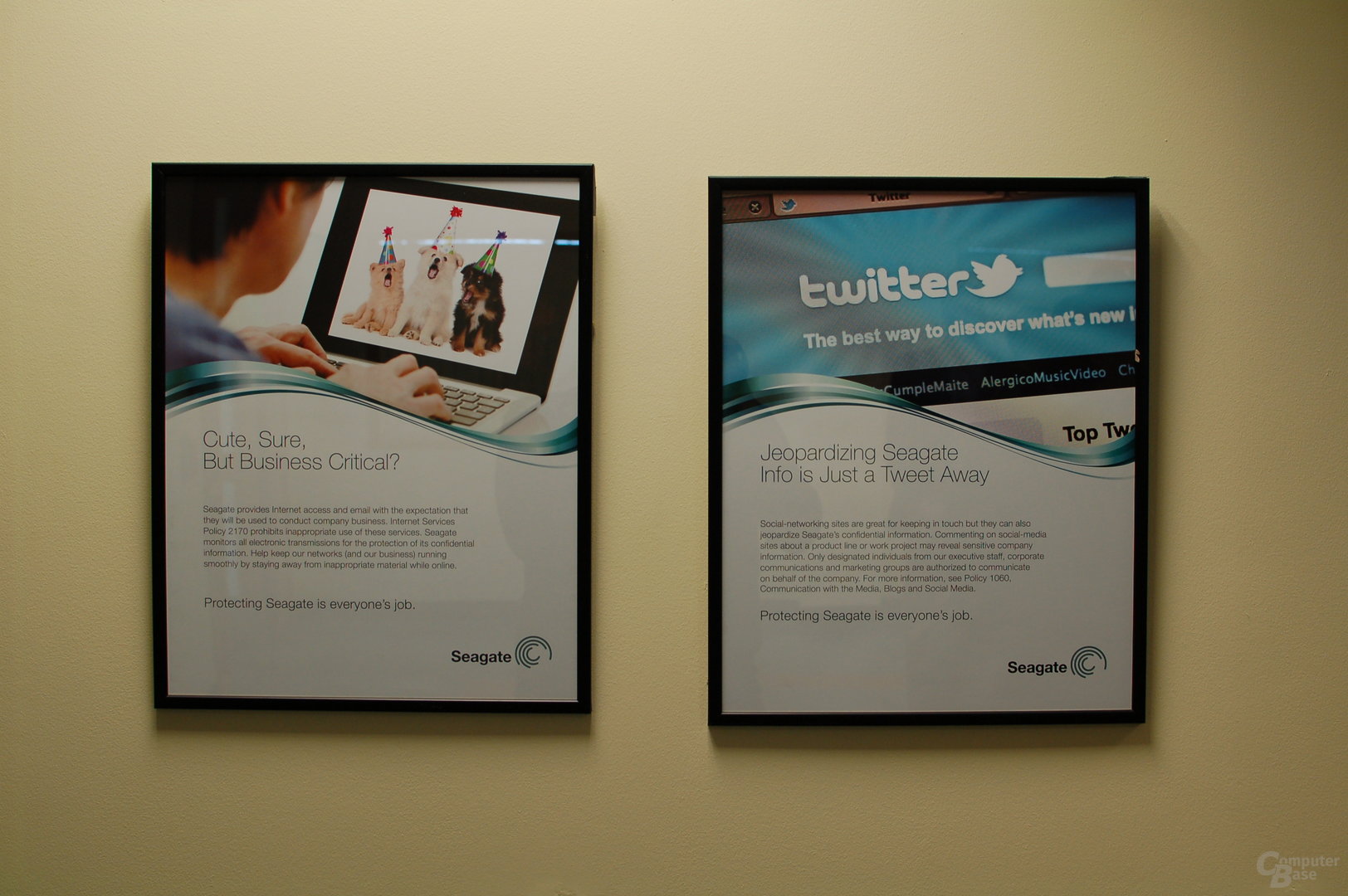

The next morning, freshly strengthened, we went to the Seagate factory, where the security guards at the entrance probably didn't expect a bunch of journalists with cameras and were initially somewhat skeptical.

But the visitor badges were ready and so it first went to the conference room, where Damien Gallagher, Executive Director Engineering, first gave an overview of Seagate and the current situation on the hard disk market as well as a few key data about the location before finally going to the factory tour ,

Unfortunately, we were not allowed into the clean rooms, the move would have taken too long. But you were probably just afraid that something might get damaged or dirty. Fortunately, there is a corridor around the clean room with many windows through which you can see all kinds of machines for processing and checking the wafers with the print heads.

In order to keep the air clean, the entire room air is exchanged and filtered several times an hour. The highest level of precision is also required to apply the layers of material, some of which are only a few atoms thick, exactly to the wafers. The entire clean room is equipped with vibration damping. Then it went back to the conference room.

Finally, Robert Lamberton, Director of Recording Head Design, talked a little out of the box about printhead technologies.

On the next page: Seagate Springtown