TDP simulation and measurement station for pastes, pads, radiators, coolers and much more in construction | igorsLAB intern

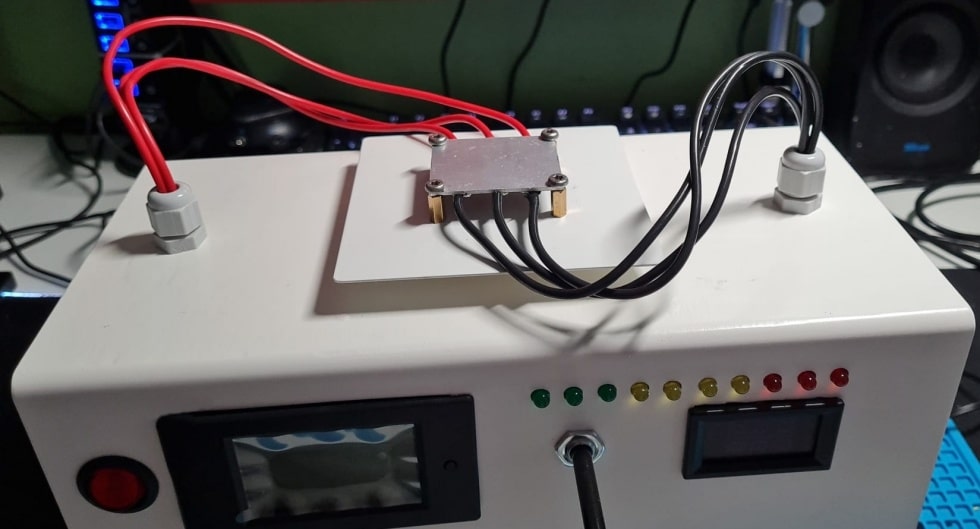

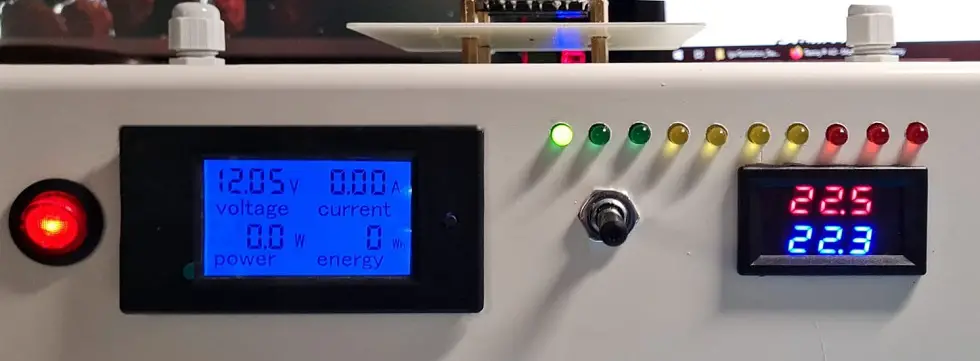

After we have already tried to set new standards for the semi-professional measurements for reviews with the fans with a reasonable amount of effort, I would like to present the next project to you today, which was about to be completed. Together with Bernhard Baumgartner from CrankzWare At the moment a digitally controlled TDP measuring station is being built, where we can later generate precisely graduated power losses (i.e. waste heat) of up to 250 watts and keep them stable to the decimal point.

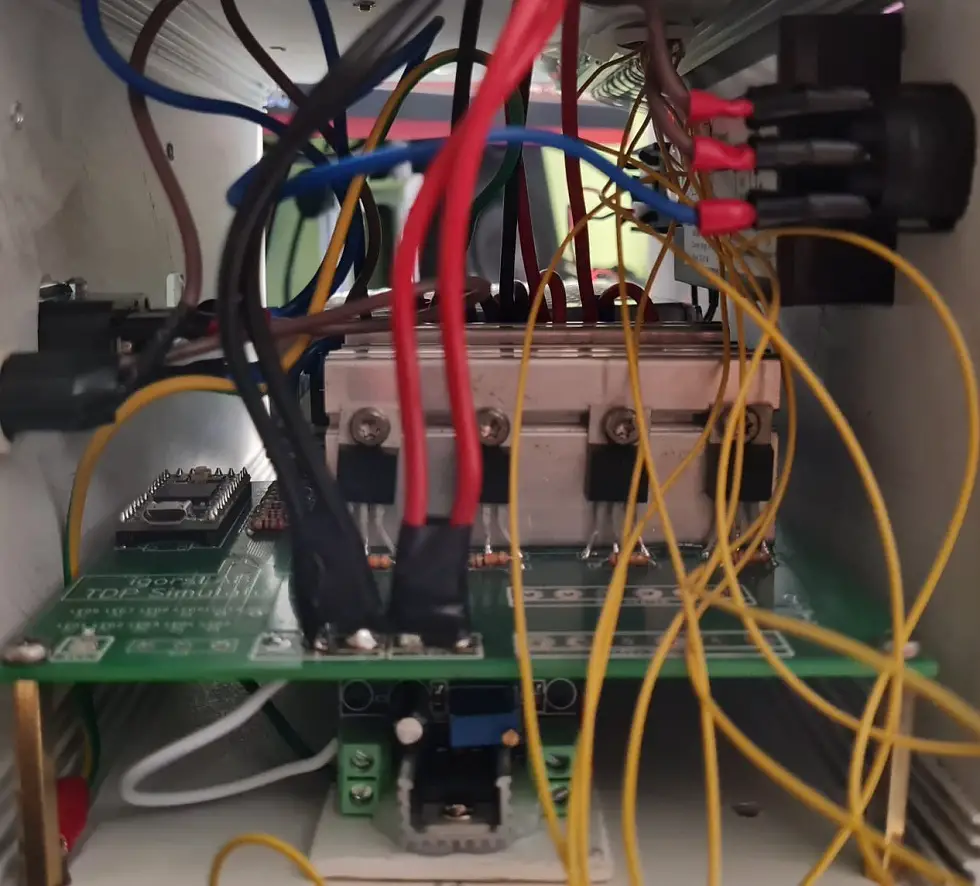

We deliberately do not work with heating cartridges or resistors (that was the first plan), but with special semiconductors in order to achieve a really precise and, above all, not so sluggish control, with which in the end it is even possible to simulate clearly defined increases in time. The necessity arose from the large number of tests that were required, because you will surely have noticed that I suspended the tests of the thermal pads for the time being. No thread in the world can withstand hundreds of attempts unscathed and in the end I just ran out of original spacers, which have to be completely replaced after each pad (up to 5 assemblies) for the sake of accuracy.

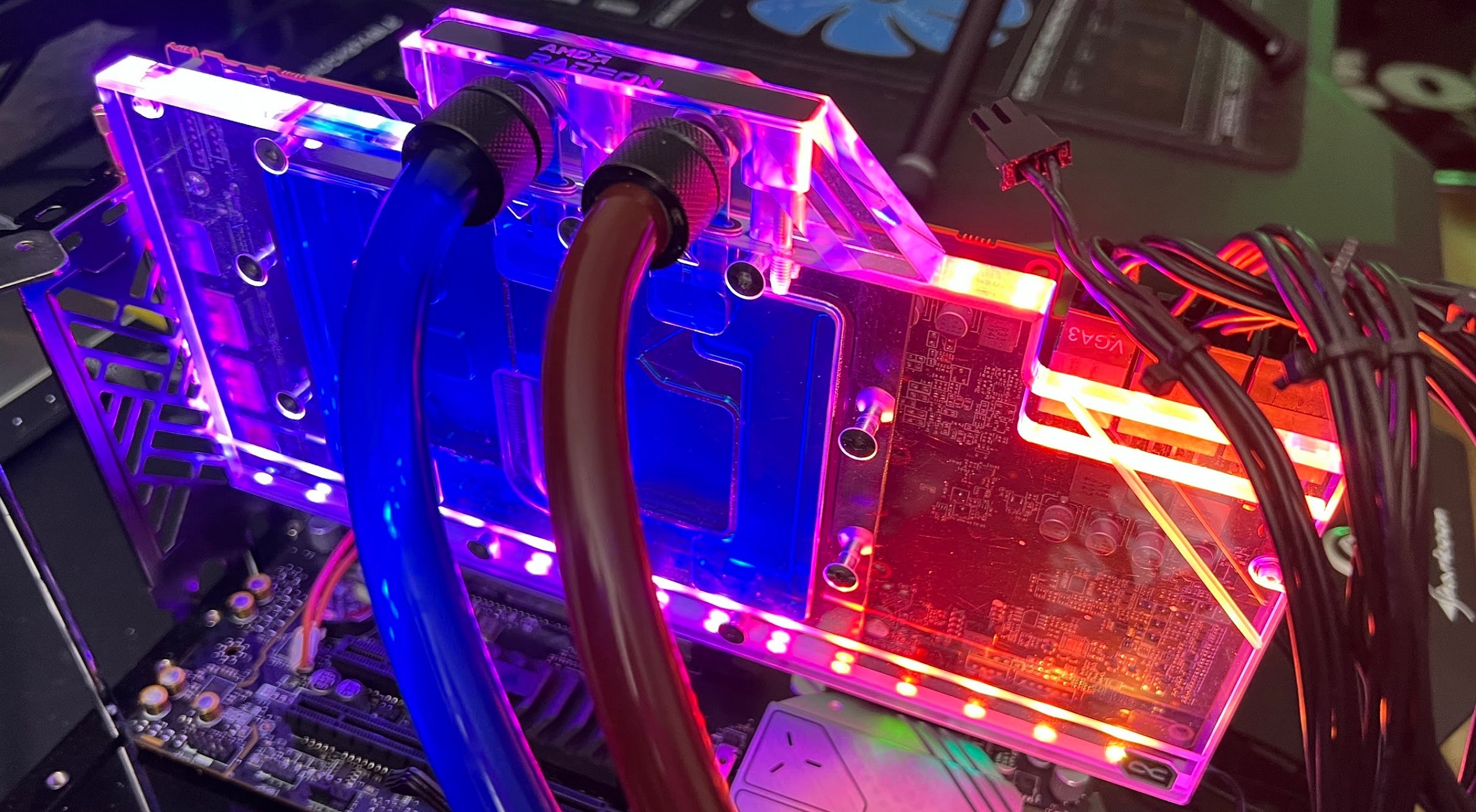

My special thanks go to Bernhard, who has meanwhile designed and implemented a PWM-controlled control system. With various attachments, we can later simulate different distances and pressures, mount coolers directly and also test radiators with a reference cooler, where clearly defined amounts of heat can be added to the water cycle. These stations can also be cascaded, so that higher levels of performance can also be implemented in the end.

We are currently still in the late alpha phase, but everything is already working quite well. Now it is time to do some fine-tuning and, after the final test, to calibrate the whole thing with the help of a professional TIM tester. Then the thermal resistance of the thermal pads should also be able to be determined quite precisely and the various distances and pressures should also allow a better adjustment to be made. It should also be possible to simulate bleeding at very high heat flux densities. My energy supplier is probably rubbing his hands together here.

Optical tuning is rather secondary, because they are everyday objects that have to take into account certain basic principles of durability and safety, both thermally and electrically. What has not been built in cannot break. By the way, we deliberately chose white, because I can, for example, use a wipeable pencil to write down the respective runs and their parameters next to the samples being tested, which the laboratory camera can then easily record. That saves the annoying paper stickers.

After completion, we will of course publish an exact construction diary and also disclose the structure, including methods and calculation bases, because transparency is logically part of it. However, the core of it all remains our trade secret, of course, because we understandably don’t want copy & paste in the end either.