At Nanyang Technological University, a team of scientists from Singapore led by Matteo Seita has developed a way to better verify the fruits of 3D printers for possible structural defects. Thanks to it, the inspection of metal 3D prints is to be significantly simplified, and this is done with the participation of an optical camera.

Thanks to the new process, inspection of metal 3D prints can be much simpler and cheaper

Elements printed in 3D, on which a lot depends (such that are used, for example, in airplanes), require a thorough verification of durability. This is difficult, for example, in the case of metal prints, which consist of a lattice of microscopic crystals and which require the use of expensive electron microscopes to determine the size, shape and arrangement of the crystals. This takes a lot of time, which is why these scientists set out to simplify the entire process.

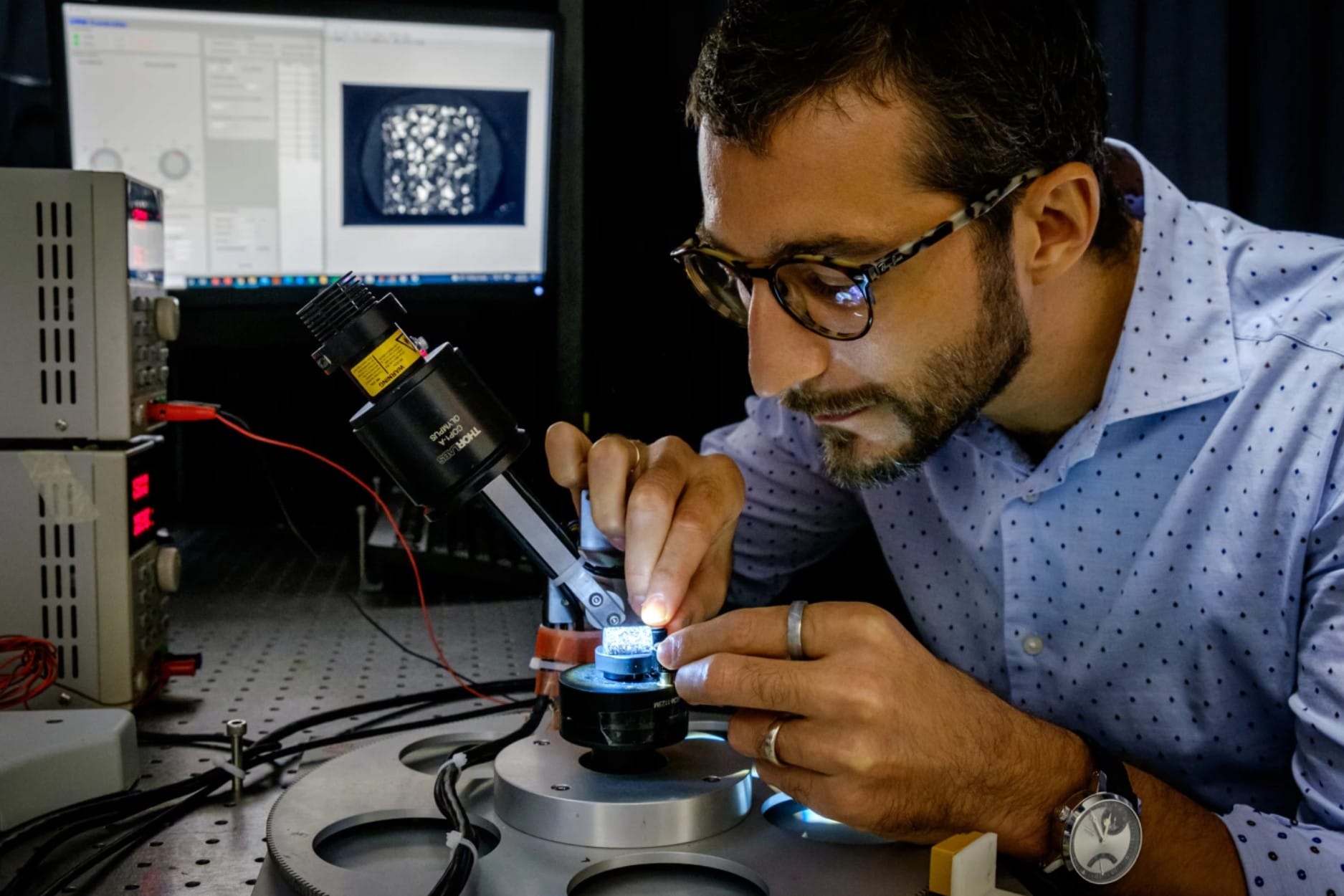

If you are 3D printing metal parts for aircraft or other critical systems, it is better that these parts are not defective. The new system allows such components to be checked for structural defects faster and cheaper than ever before. In practice, it includes an optical camera, a light source, and a portable computer with a machine learning application, which costs around $ 18,400, not even a million dollars for the microscope in question.

Also read: Graphics card for Raspberry Pi CM4. The power is not overwhelming, but you can browse the Internet

The process begins with chemically etching the surface of the printed object, revealing the alloy microstructure, and taking a series of photos with a gradually shifted illumination angle. The software then determines the shape, size and orientation of the microcrystals by analyzing how they diffuse reflected light in different photos. This information, in turn, can be used to determine the strength and durability of an object, and it only takes 15 minutes.