Researchers from ETH Zurich and the University of Friborg set out to facilitate the work of professionals involved in the production of anything from a composite by creating a completely new composite material that, under UV light, will begin to fluoresce when it approaches the breaking point under mechanical stress.

Scientists have developed a new composite material that fluoresces in response to external mechanical forces

Materials with a heterogeneous structure, i.e. composite materials, are used, among others, in construction or aviation, where their durability must be thoroughly tested before putting into use. You can traditionally play with the trial and error method, looking for their endurance limit, but you can also make your work easier and faster, for example by using this new experimental composite material.

Also read: Small thermoelectric generators from a 3D printer within the range of the new filament

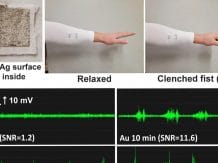

This one consists of laminated alternating layers of two materials. The first one is a synthetic mother-of-pearl with strength, hardness and stiffness similar to the natural one. It is built by aluminum oxide plates connected to each other by means of epoxy resin and titanium oxide particles. The second layer is a plastic polymer that contains mechanophores, particles that are usually pale pink when viewed under ultraviolet light, but when stretched out, begin to fluoresce purple.

Thanks to this combination, this new composite material when viewed under UV light clearly indicated the moment (degree of force used) at which it was starting to bend. However, this did not mean that it was about to break, because in fact the brightness of the violet indicated the degree of force that was exerting on it, which opens the door to a more detailed examination of the strength of a given composite. Especially since later exposure to green light caused the mechanophores to revert to their default pink color.

Also read: 5G stability problem solved by signal splitting

Unfortunately, this new composite is currently in the experimental phase and its production is referred to as a laboratory scale. Scientists now need to demonstrate the potential of the fruit of their work to kick off mass production, and their work is featured in a journal publication ACS Applied Materials and Interfaces.